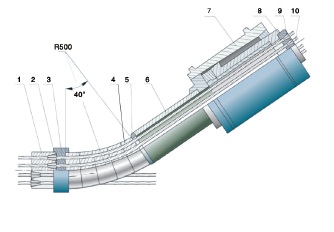

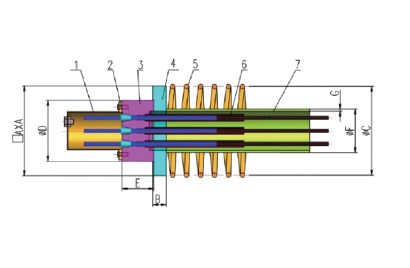

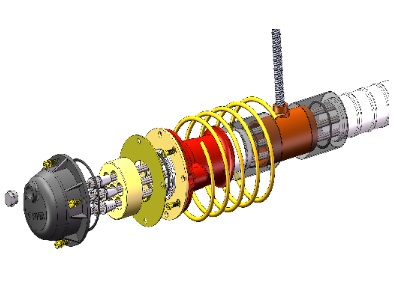

Post-tensioning system

OVM specializes in designing, manufacturing, and installing reliable post-tensioning systems. Our solutions adhere to international standards and are suitable for both new and existing structures

Post-tensioning has transformed concrete structure design and construction, enabling the use of thinner concrete sections, longer spans, and more durable structures. It has also led to the development of innovative construction techniques, making bridge construction faster, simpler, and more cost-effective. This technique involves installing tendons within a concrete element and applying tension, creating compressive stress in the material. This counters tensile stress caused by external loads, reducing or preventing deformation and cracking.

Post-Tensioning: Enhancing Design, Efficiency, and Sustainability

Greater Design Flexibility

Post-tensioning enables a wide range of geometric and architectural possibilities, allowing for complex curves, variable elevations, and long free spans without the need for intermediate supports.

Cost and Time Efficiency

By reducing the amount of concrete and steel required, post-tensioning lowers both material costs and foundation work. It also enables the rapid assembly of precast elements, accelerating the construction process and improving site efficiency.

Enhanced Durability, Reduced Maintenance

Post-tensioning minimizes the need for joints, which reduces the frequency and cost of maintenance. For applications such as tanks, silos, and reservoirs, it results in concrete that is virtually crack-free, offering better protection against corrosion.

Environmental Benefits

Post-tensioned structures require fewer materials, such as steel reinforcement and concrete, leading to lower greenhouse gas emissions during production and transport.

Do you have a project in mind?

You have a question about our solutions or you already have a project in mind? Please fill out the form below and our teams will get back to you shortly.